Vision Inspection Systems for Quality Control

What is a Vision Inspection System ?

A vision inspection system uses cameras, sensors, and advanced algorithms to inspect products for defects. These systems are often integrated into production lines to perform real-time quality checks. Unlike manual inspections, vision systems offer unparalleled speed, consistency, and accuracy, making them an indispensable tool in modern manufacturing.

How Do Vision Inspection Systems Work ?

Vision inspection systems operate in three main stages:

-

1. Image Acquisition

High-resolution cameras capture images or videos of the products as they move along the production line. Lighting is carefully controlled to ensure the system can detect even the smallest imperfections. -

2. Image Processing

Advanced software analyzes the captured images, comparing them against pre-set standards or models. This step involves identifying defects such as cracks, scratches, misalignments, or deviations in size and shape. -

3. Decision-Making and Sorting

Based on the analysis, the system classifies the product as “pass” or “fail.” Failed products can be automatically removed from the production line to ensure only top-quality items reach customers.

Benefits of Vision Inspection Systems

-

Enhanced Accuracy: Vision systems can detect minute defects that might be overlooked during manual inspections.

-

Increased Efficiency: Automated inspections can process thousands of products per hour, significantly boosting production rates.

-

Consistency: Unlike human inspectors, vision systems don’t suffer from fatigue, ensuring consistent performance.

-

Cost Savings: By reducing defects and minimizing waste, these systems lead to significant cost savings over time.

-

Improved Safety: Automated inspections eliminate the need for workers to be in potentially hazardous environments.

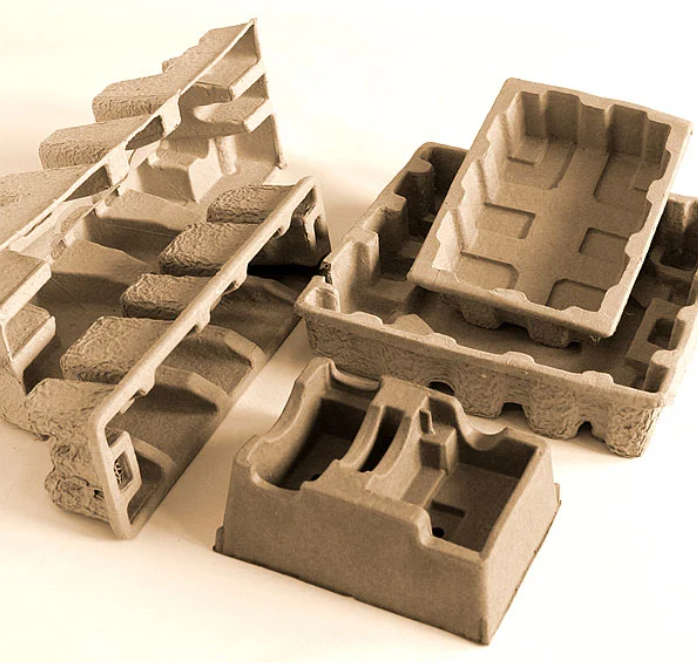

The Role of Vision Systems in Pulp Molded Products

Pulp molded products, such as bowls and plates, are increasingly popular due to their eco-friendly nature.

However, ensuring the quality of these products can be challenging due to their complex shapes and varying textures.

Vision inspection systems offer a reliable solution by:

1. Detecting cracks, uneven thickness, and other structural defects.

2. Ensuring consistent & even product barrier coating to meet food safety.

3. Streamlining the inspection process, reducing manual labor.

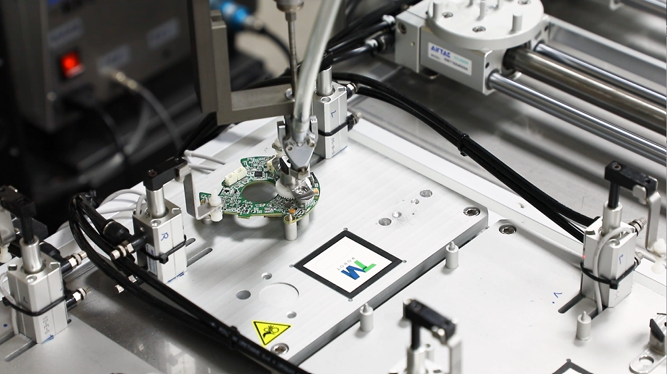

Our Vision Inspection System for Pulp Molded Bowls

At HYC Singapore, we specialize in vision inspection systems tailored for the pulp molding industry.

Our state-of-the-art solution ensures the quality of pulp molded bowls through a conveyor system that passes products through a vision enclosure.

This setup guarantees accurate and efficient defect detection, helping manufacturers deliver top-quality products consistently.

Learn more about how our vision inspection system can transform your production line by visiting our PRODUCT page.