Infrared Heating Technology

Infrared Heating Technology

Infrared heating technology has gained significant traction in industrial environments due to its efficiency, versatility, and ability to target heat directly where it's needed. By using infrared radiation to heat objects and surfaces directly, rather than the surrounding air, infrared heating offers several advantages for industrial applications, from energy savings to improved working conditions. Below is an overview of the benefits, applications, and reasons why infrared heating is an ideal solution for many industrial settings.

How does Infrared Heating Technology work ?

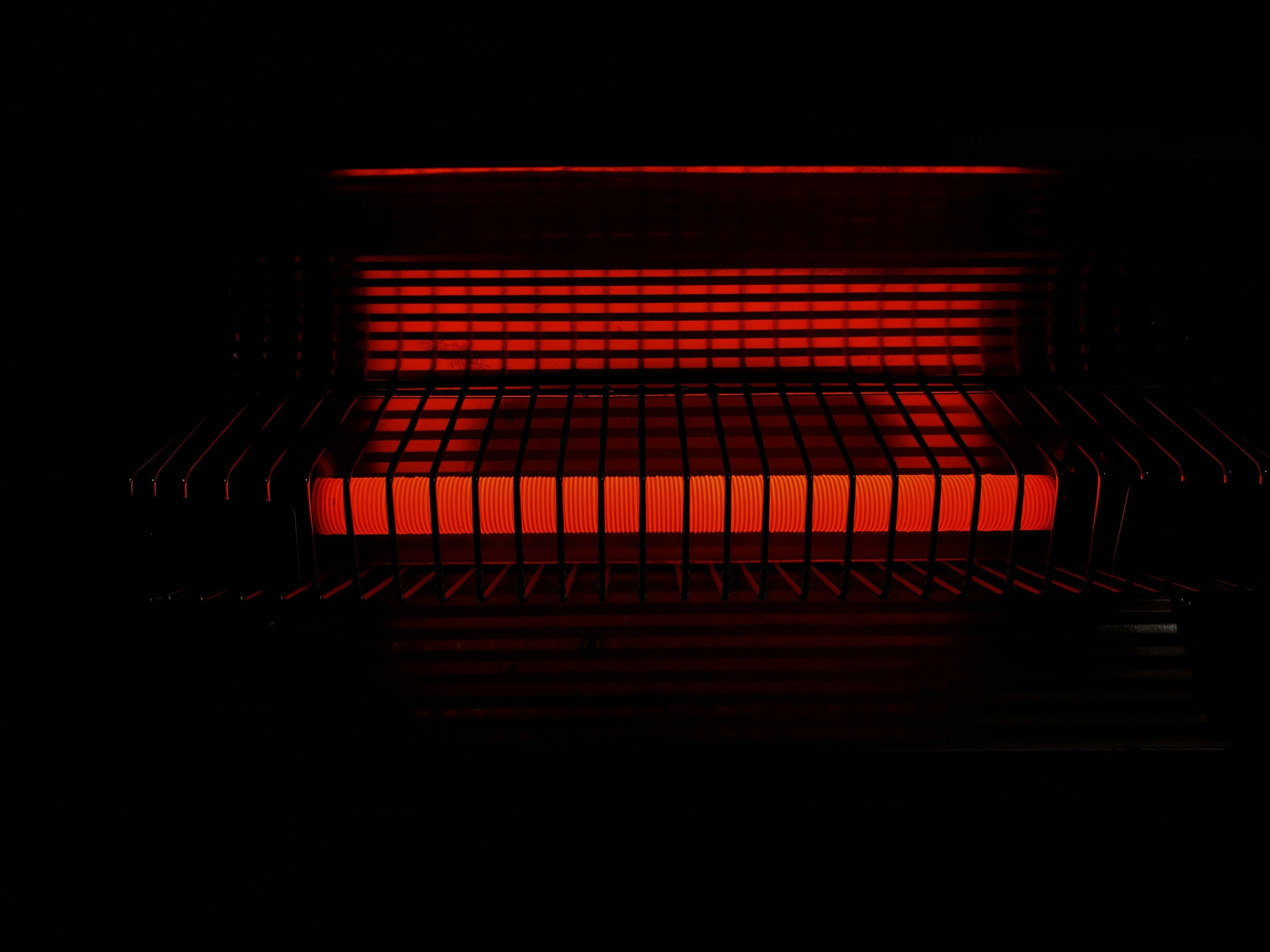

Infrared heaters emit radiant heat in the form of infrared rays, which are absorbed by objects and surfaces in their path. Unlike conventional heating systems, which heat the air and rely on circulation, infrared heating directly warms solid surfaces, materials, and even people. This makes it an effective, targeted, and efficient solution for large industrial spaces or specific production processes.

Benefits of Infrared Heating Technology

-

Energy Efficiency

- Infrared heaters only heat objects and surfaces, rather than the air, which results in less energy consumption. This targeted heating approach minimizes wasted energy and reduces heating costs, making it more cost-effective than traditional heating methods, especially in large, open industrial spaces.

- Because infrared systems warm objects directly, they deliver faster results and immediate comfort, avoiding the need to wait for air temperature to increase.

-

Faster Heating Times

- Infrared heating systems provide immediate warmth, unlike traditional heating systems, which take time to warm up the air. This makes infrared heaters particularly beneficial in industries where quick and efficient heating is essential for production processes.

-

Consistent & Even Heat Distribution

- Infrared heating delivers uniform heat distribution, reducing cold spots and creating a comfortable working environment. This is especially useful in large warehouses, factories, and production floors where uneven heating can lead to discomfort or inefficiency.

-

Reduced Air Circulation

- Traditional heating systems often rely on forced air circulation, which can stir up dust, allergens, and moisture. Infrared heating doesn’t rely on air movement, resulting in cleaner air and reduced contamination risks in sensitive environments.

-

Targeted Heating for Specific Applications

- Infrared heating can be directed toward specific equipment, machinery, or materials, making it an ideal solution for applications like curing, drying, and pre-heating in industries such as manufacturing, construction, and food processing.

Why Choose Infrared Heating for Industrial Applications?

-

Cost Savings

With lower energy consumption and faster heat delivery, infrared heating offers long-term savings on energy bills, especially in large industrial spaces.

-

Environmental Impact

Infrared heating is more eco-friendly, as it minimizes energy loss and operates with less CO2 emissions compared to traditional heating methods.

-

Minimal Maintainance

Infrared heating systems require less maintenance than conventional heating systems, reducing downtime and overall operating costs.

-

Safety & Regulation Compliance

Infrared heating systems are safe to operate in industrial environments, with many models designed to meet regulatory standards for safety and reliability.

Application of Infrared Heating Technology

Here at HYC Singapore, we apply this technology within our THEROS Industrial Oven product line, leading to efficient and effective heating of products.